Advantages of Flexible Rubber Collets in Shaft Processing

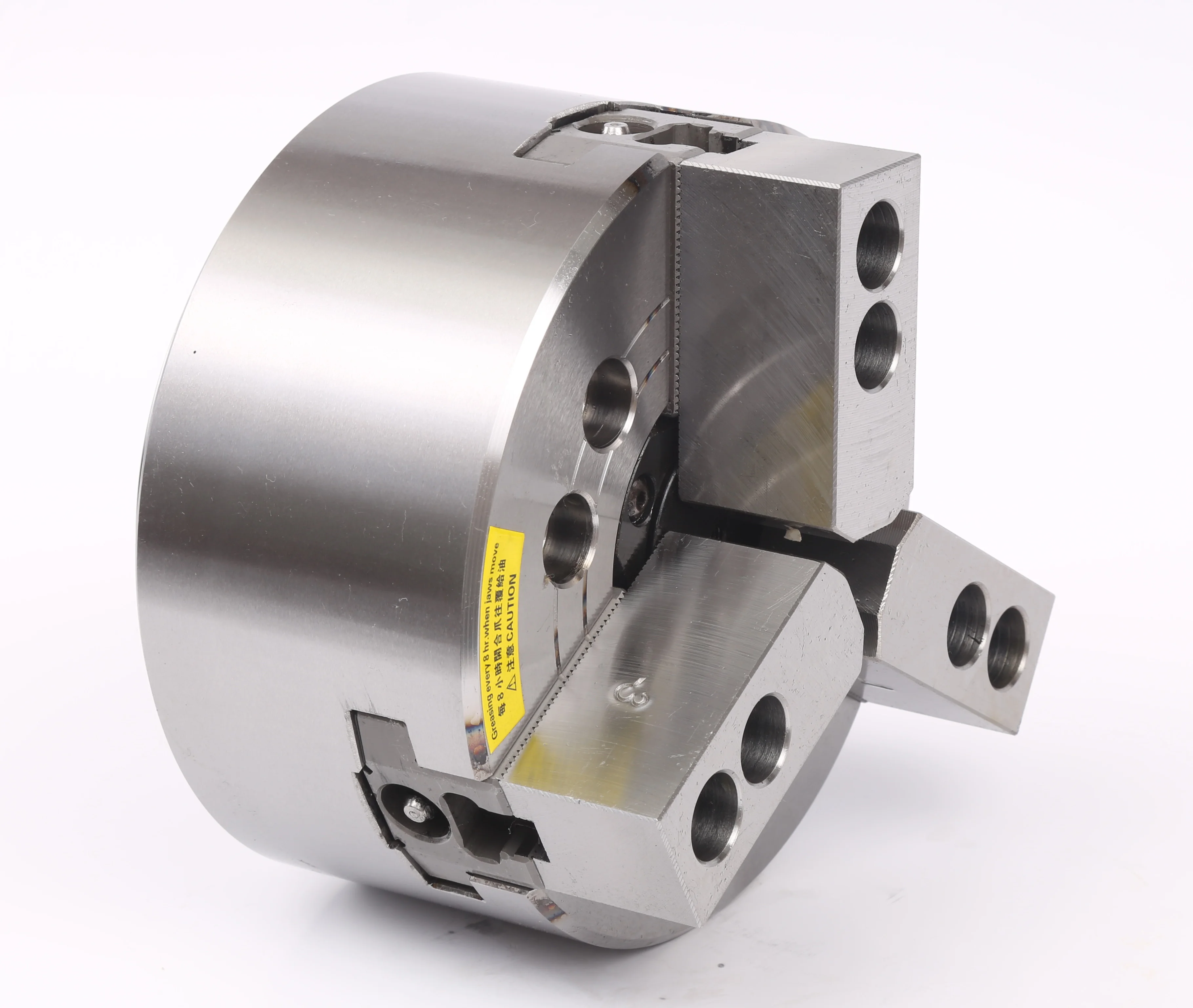

Traditional CNC lathes for shaft workpieces typically use general-purpose fixtures, such as "through-hole hydraulic chucks or spring collets".

General-purpose chucks have significant shortcomings in large-scale, high-precision production:

•Poor precision

•Slow clamping speed

•Jaw or collet flaring

•Frequent trimming of jaws required

•Gaps in the collets easily allow iron filings to enter

•Spring collets cannot clamp or hold workpieces once they reach metal fatigue strength

Why Flexible Rubber Collets Stand Out

- High Precision up to 0.005mm

- Fast Clamping Speed

- Enhanced Sealing to Prevent Iron Filings

Flexible rubber collets are designed to overcome these limitations. Made with vulcanized rubber, they maintain consistent clamping force and prevent deformation during machining.