KORRETTO Chuck Application Cases

Advantages of Rubber Collets in Shaft Processing

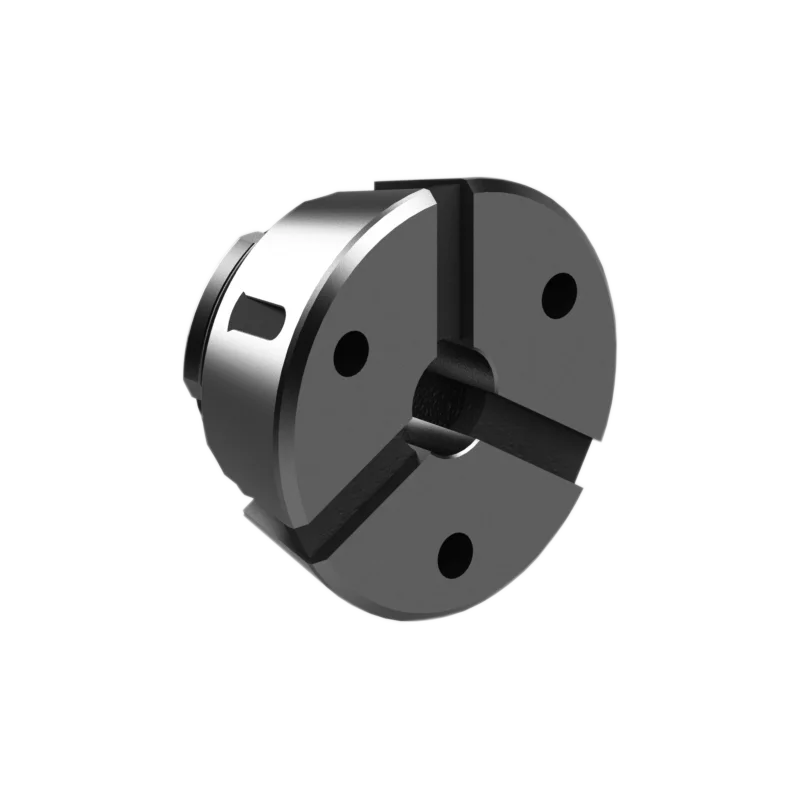

Traditional CNC lathes for shaft workpieces often use general-purpose chucks like "through-hole hydraulic chucks" or spring collets.

- Poor precision

- Slow clamping speed

- Jaw or collet flaring

Three Typical Machining Methods for Valve Workpieces: Pros and Cons

The three most efficient methods for valve and tee pipe fitting machining are:

- Double-head lathes

- Three-face boring and milling machines

- Indexing chucks

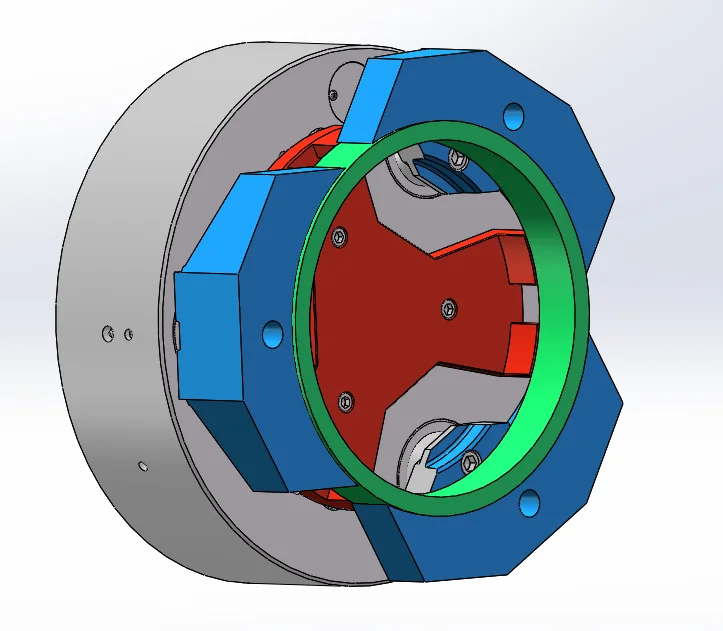

Application Case of Pull-back Chucks

The customer's workpieces are thin-walled and require high precision in end-face positioning. A pull-back hydraulic chuck with fan-shaped jaws is used to distribute radial clamping forces and reduce deformation.

- Converts radial clamping force into axial pull

- Minimizes workpiece deformation